| CLIENT | Chala |

| LOCATION | Medellin, Colombia |

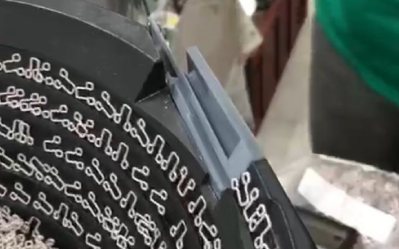

| MATERIAL | Onyx and fiberglass |

| APPLICATION | Input for hopper |

| INDUSTRY | Textile industry |

operating efficiency

cost savings excluding import costs

savings in delivery time vs. import time

This element wears out with the handling of the operators over time. Due to its complex geometry, it is not possible to machine the part in one block, but the element has to be divided into 3 different parts.

After analyzing the geometry of the element and taking advantage of the benefits of this technology to reproduce complex geometries, we designed a model that meets all the requirements of simpler functionality. The prices of the spare part and the delivery time were substantially reduced.

An original piece made up of three independent parts

CAD design of its components in one.

Only one piece is required and no assembly holes are necessary.

3D printing in Onyx with fiberglass

Maribel Restrepo – Chief mechanic and maintenance area.